Roof waterproof and heat reflective functional coatings, UV resistant and heat-insulating coatings, heat-resistant coating

Place of Origin: Guangdong, China

Product name: Heat insulation and waterproof paint,Anti-UV Roof Coating

Material: Modified acrylic polymer

Usage: Building Coating

State: Liquid Coating

Function :Anti UV-rays

Appearance: White Color Liquid Viscous Paint

Effect: Excellent Cooling Effect

Feature: Environmentally friendly and safe, durable and long-lasting

Application : Building Exterior Wall or Roof

Usage Feature : Heat insulation waterproof coating

Application Method :Brush, Spray, Roll

Drying time: Surface dry for 1 hour. Fully dry for 24 hours

Packing: 20kg/Barrel

Advantage: With medium to high quality options, super high cost performance

Product Features

These are the problems that this product aims to solve: the steel structure roofs with coating that waterproofs and reflects the heat are 1ikely to 1eak; besides, the original coating of the color steel on the surface of the roofs tends to age and rust; what’s more, color stee1 p1ates are prone to absorb and conduct heats, thus raise indoor temperatures during summertime; therefore, color stee1 plants generally need to be coated and renovated after 3-5 years as of being put into use, for the purpose of stopping the leaking, 1ower energy costs, thus prolong the service life of the roofs. Also, after long period of service, the concrete fafade would start to crack and powder, giving rise to water leaking.Hence there is also need to maintain the waterproof layer on the concrete surface,enforcing the protection of the building.

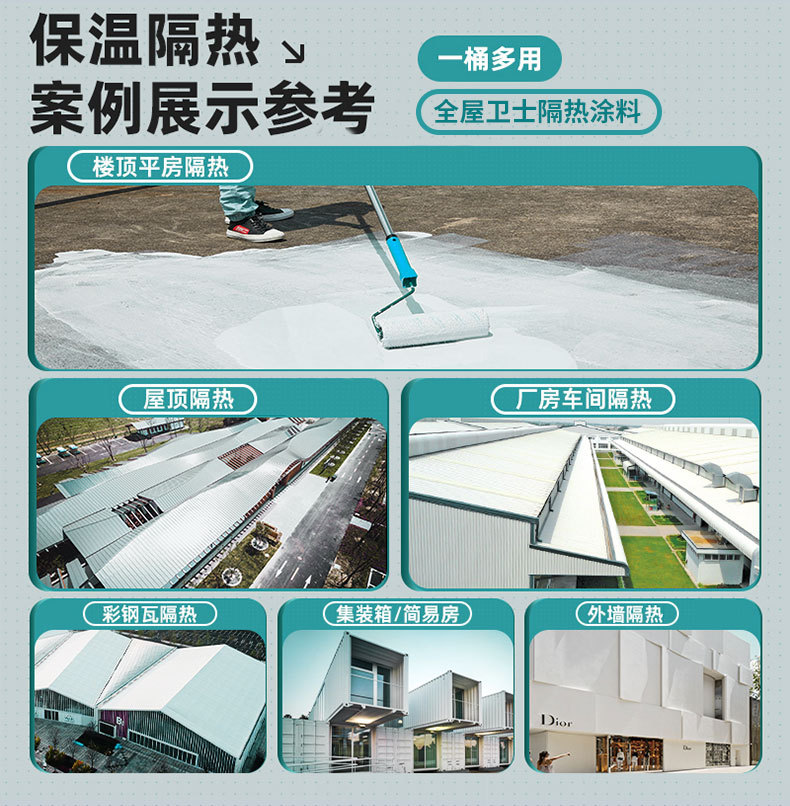

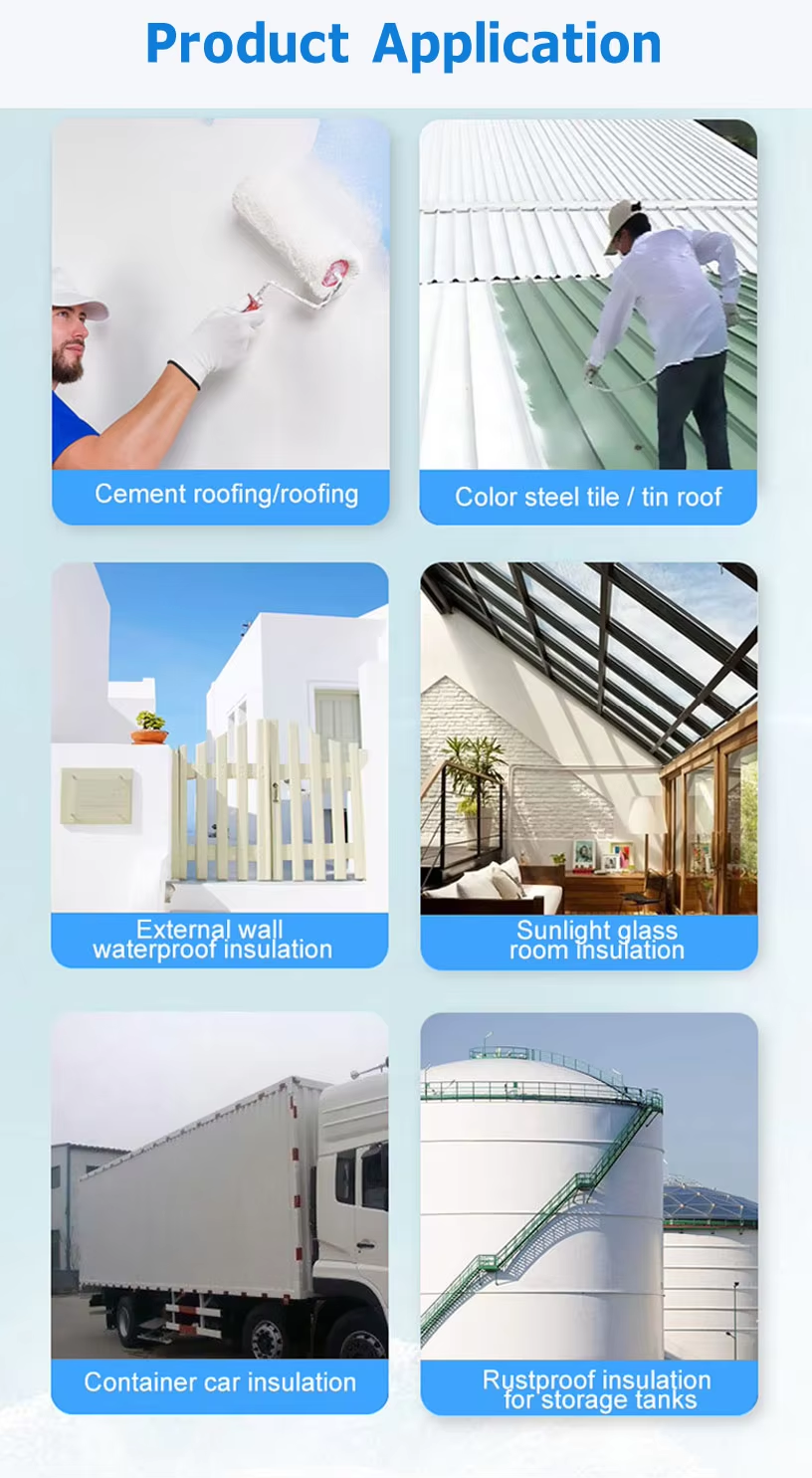

Scope of Application

Color steel tile plants,netal rooftops,rooftops,concrete external wa11s,granary,1arge-scale warehousing roofs, outdoor storage tanks (o11 tanks,chemical tanks,spherica1 tanks,storage tanks) surface and other thermal insulation and energy-saving projects.

Usage Method

1. The color steel tile substrate must be stable, not shake, and free of dust and oil impurities. Rusty substrates should be polished clean with a grinder, rinsed with a high-pressure water gun, and dried, or treated with rust fixing agents to convert and fix rust.

2. Before the construction of concrete substrate, the surface to be painted must be cleaned to ensure dryness, no grease, dirt, mold, algae and other attachments. New gray sand, batch sand, and cement surfaces should be dried thoroughly (it is recommended to spray a layer of primer on cement substrate).

3. Open the material barrel and use a mixing tool to evenly mix the heat reflection insulation coating. Use a sprayer or drum to evenly spray the heat reflection insulation coating on the processed substrate, cross spray twice, and spray the second coat after the first coat is completely dry and solid to ensure the thickness of the coating. Do not reduce the material by stealing work (if it is too thick for construction, it is recommended to add water at a ratio of 10% -15% of the weight of the coating).